|

Ningbo Liqin Industry & Trade Co.,Ltd.

|

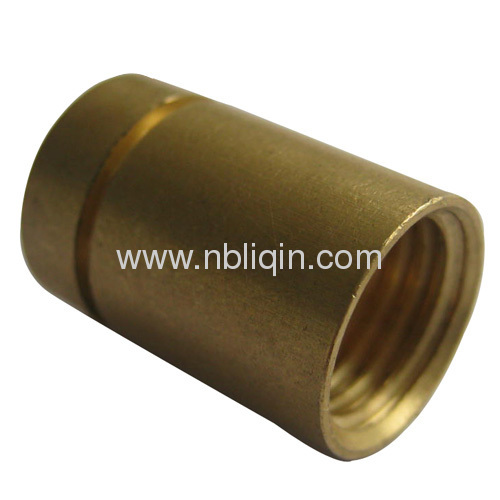

Machining Copper Parts

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Process: machining

2.Used in refrigerant parts

3.Certification:ISO9001

Plumbing Part Copper connector

1.High density copper parts

2.Hood abrasion resistance&hardness

3.High precision copper parts

Machining Copper Parts :

1.High density copper parts

2.Hood abrasion resistance&hardness

3.High precision copper parts

Process: machining

Weight: 8.6g

Used in refrigerant parts

MOQ: 50000PCS

1).Machining facilities: wire cutting machine CNC turning machine deburr all sharp edges

1).Machining facilities: wire cutting machine CNC turning machine deburr all sharp edges

2).Factory facilities: CNC horizntal boring and milling machine,,Surface Grinder,wire cutting,Milling Machine,CNC Lathe.

3).CNC machining Parts, CNC machined parts, mechanical parts ,high precision metal parts are produced according to customers' drawings or samples

4).Finish: nickel plating, zinc plating, eletropolishing according to customer's requirements.

5).Professional CNC equipment ,bright silver white color , high precison . excellent quality , competitive price , faet delivery time ,good service.

Machining Copper Parts :

(1) .Material stainless steel ,cold work steel ,Spring steel , martensitic steel,aluminum ,brass, bronze,copper, according to customer request

(2).High Tolerance :0.01mm

(3).Certification :ISO9001

(4).Technical Machining skill

(5).The product is manufactured by cnc lathe;cnc miller;grinding;tapping;bending

(5).The product is manufactured by cnc lathe;cnc miller;grinding;tapping;bending

(6).We can accept clent's drawings to meet individual requirment ,the enginer will give the best process for cost saving and time.

(7).Surface treatment : Zinc / Nickel /Silver /golden plating ;White /black/red/blue/yellow anodized ; passivated ; electropolshed ;sanding;powering

Machining Copper Parts

Machining Copper Parts

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Machining Parts

CNC Machining Parts

Brass Machining Parts

Oem Machining Parts

Metal Machining Parts

Stainless Steel Machining Parts

More>>